We recently developed a cleanroom track ISO class 4 for working in special circumstances. As the description suggests, a “cleanroom” is an environment in which hardly any dust particles should be released. They are often human-free, enclosed environments in which only robots perform automated work without physical intervention by humans.

With the support of the Flanders Agency for Innovation and Entrepreneurship, the Limburg company has now developed a track on which these robots have a greater working range than just their axis and the length of their arm. The developed track has a length of 3 m. But this can be increased up to 100 m long in principle, with a maximum length of 12 m in one piece.

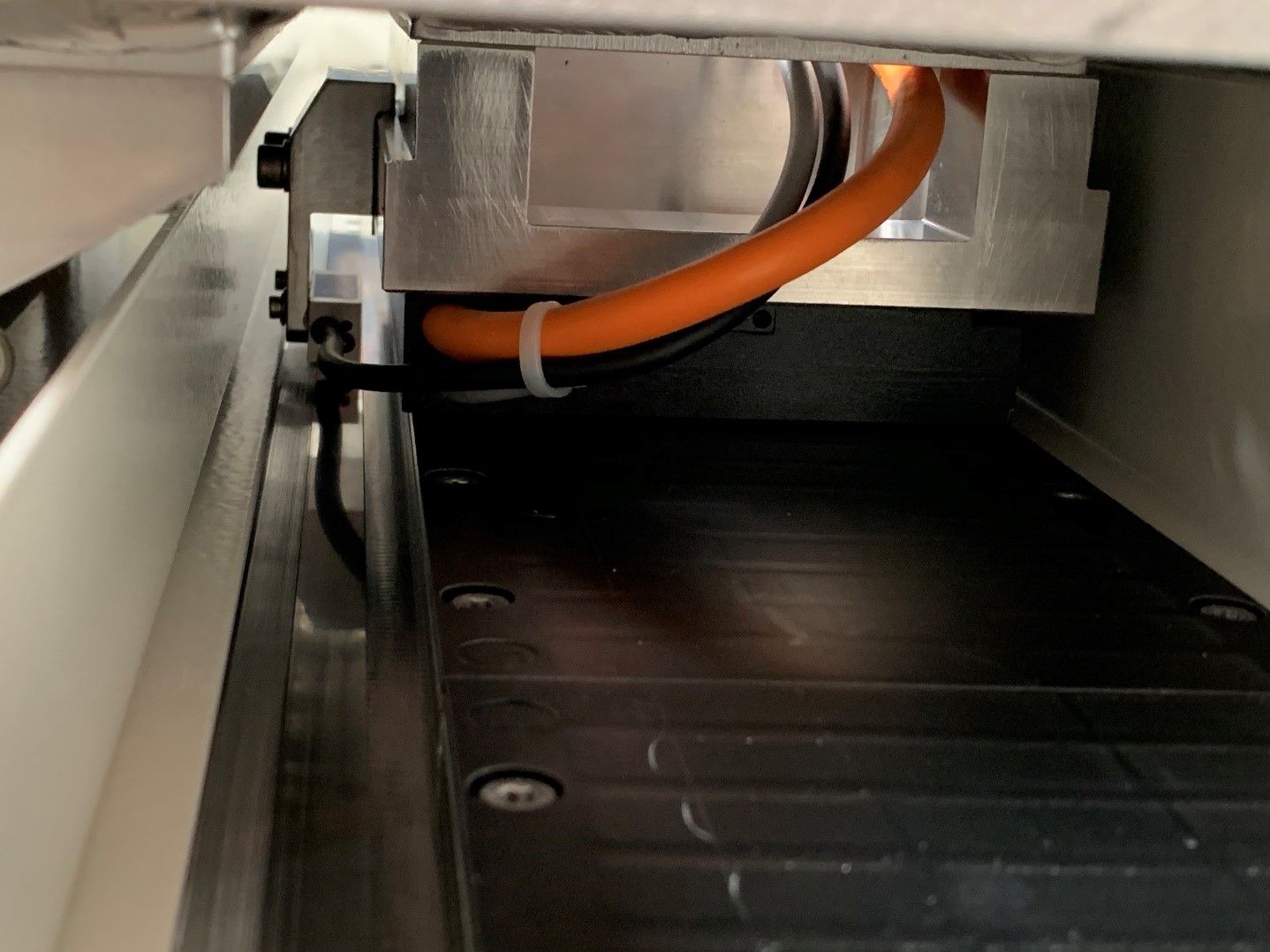

What’s special about this track is that it doesn’t work with a local exhaust to remove the dust particles; it simply creates exceptionally few dust particles instead. This is due to the fact that the robot carriage is driven by a linear motor. This is much more beneficial for avoiding contamination than the usual drive mechanisms Vansichen uses for its tracks: namely a belt or a gear rack.

The tests for ISO certification were conducted by the German Fraunhofer Institute in Stuttgart. ISO class 4 was achieved (the lower the ISO class, the less contamination). This puts the Vansichen track a class ahead of the of the ISO class 5 self-propelled robots. The requirement for cleanroom equipment is particularly broad; it is common in the pharmaceutical sector, as well as the food sector. The demand for cleanroom conditions will continue to increase in the coming years according to Vansichen. This track means the company also completes the complete range of tracks linked to the robots that the Japanese robot manufacturer, FANUC, can offer.