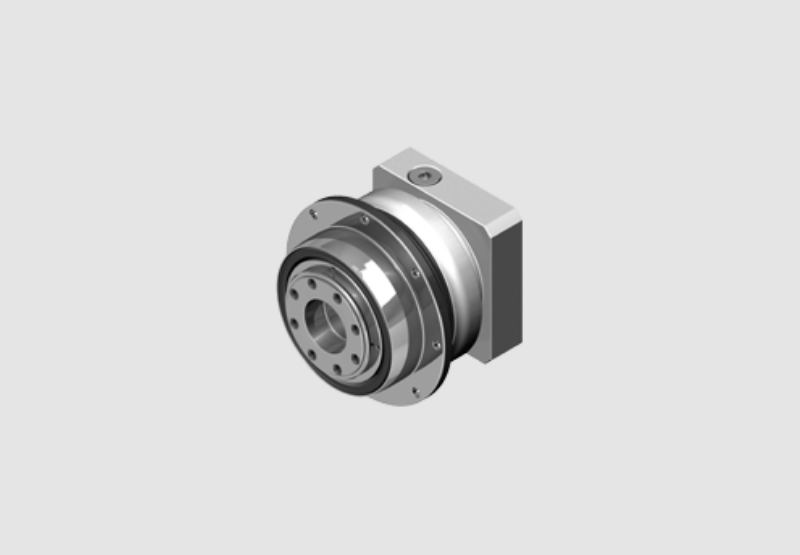

APEX DYNAMICS: PLANETARY GEARBOX

The most innovative applications, such as Robotics, 3D printing, etc. all have one thing in common: a planetary gearbox forms the basis of their drive. Located between the motor and the load, this gearbox provides an increase in drive torque and a decrease in speed, improving the mass inertia ratio. Usually, for these reducer units, the input and output shafts are aligned. The advantage of this is that they can be built relatively small and yet transfer high torque.

The box may consist of several torque transfer steps, the smallest overall ratio being 3:1 and the largest being 10:1 for one step. Both straight and bevel teeth are possible. If there are restrictions for the installation space of the motor, there are also right-angle planetary reducer units with additional bevel gears to ensure the corner does not create a problem.